When Richard Mille and Ferrari began collaborating in 2021, it wasn’t just about putting a logo on a dial. It was about speaking a shared language, one built on performance, precision and the pursuit of something more than mechanical mastery.

Ferrari, after all, doesn’t build cars. It sculpts velocity. And Richard Mille? He doesn’t just make watches. He engineers wearable machines.

Their latest cocreation, the RM 43-01 Tourbillon Split-Seconds Chronograph Ferrari, reflects that meeting of minds. It’s not merely inspired by the world of racing. It moves like it.

Limited to just 150 pieces, split evenly between satin-finished grade 5 titanium and the brand’s signature Carbon TPT®, the RM 43-01 is more than a timepiece.

It’s the distillation of three years of dialogue, design and daring.

“We have two cases to express two distinct personalities,” says casing technical director Julien Boillat.

Thank you!

For signing up to our newsletter.

Please check your email for your newsletter subscription.

“A ‘gentleman driver’ ethos in the titanium version, and a more high-octane attitude in the carbon one.”

But the journey to get there, across countries, disciplines and traditions, tells the real story.

“The way they handle those tiny components is stunning. It doesn’t seem possible for a human to work on them with such precision."

- FLAVIO MANZONI, FERRARI

A merging of two worlds

Les Breuleux in Switzerland and Maranello in Italy are separated by about 600 kilometers. But for the teams behind the RM 43-01, the distance quickly became irrelevant.

“The most important thing is to respect the brand identity and values,” says Gianfranco Saracino of Ferrari’s Centro Stile.

“It’s easy to arrive somewhere and just begin disrupting. It’s more difficult and rewarding to merge the two worlds.”

This wasn’t about Ferrari adapting to watchmaking or Richard Mille to racing. It was about creating something that neither could’ve built alone.

. (Photo courtesy of Richard Mille/.)

On both sides, design directors sketched, reworked and reimagined, each inspired by the other’s obsession with detail.

For Salvador Arbona, Richard Mille’s movement director, the design process was less about imitation and more about translation.

“We looked at the colors, materials and fabrics Ferrari uses. We were interested in the materials and finishing that would deliver a 3D aspect in the movement,” he says.

Gradually, what began as an exchange turned into trust.

Teams shuttled between Maranello and Les Breuleux, pushing boundaries and challenging assumptions. What could be moved? What had to remain untouched? Where was the line between innovation and tradition?

“We always use the best materials, original, regardless of cost,” Arbona says.

“Durability is a core value.”

This approach became a shared philosophy, built into every layer of the timepiece.

Bespoke engine

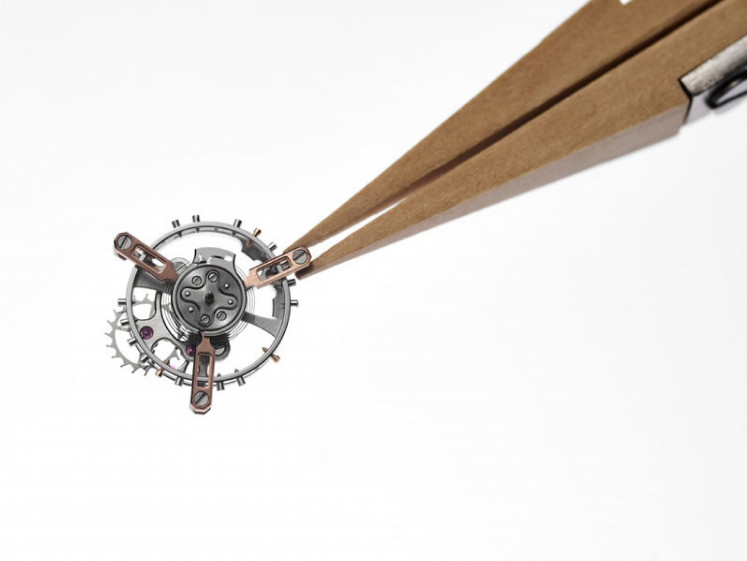

At first glance, the RM 43-01 impresses with its complexity. But its real innovation lies beneath the surface, in a movement completely redesigned from the ground up.

. (Photo courtesy of Richard Mille/.)

“We don’t want to over-complicate it; a movement intelligently built, with an assembly logic and a real understanding of the constraints each part must endure, makes it an example of durability and reliability,” Arbona explains.

The result: A caliber that houses over 500 components with a 70-hour power reserve.

At the center is a split-second chronograph paired with a tourbillon, two of horology’s most challenging complications. Richard Mille’s long-time engineering partner, Audemars Piguet Le Locle (APLL), played a critical role in refining this mechanism.

“When we design a watch, we find ways to increase the performance and to discover new materials that improve durability yet further,” Boillat says.

Through scientific simulations, the team developed a new generation of components that optimize consistent torque across a 70-hour power reserve, without compromising precision.

A reserve indicator at 2 o’clock shows how much energy is left; the torque display at 11 prevents overwinding. The result: a mechanical dashboard that interacts with the user in real time.

. (Photo courtesy of Richard Mille/.)

The movement sits on a skeletonized grade 5 titanium baseplate, reinforced by bridges produced from both titanium and Carbon TPT®.

The entire construction is light and resilient. The RM 43-01 is engineered to endure racing or extreme conditions.

The new RM 43-01 takes the codes of the company’s design, so that it’s instantly recognizable as a Richard Mille creation. But on this watch, Arbona took some risks, notably in deciding to move the tourbillon cage.

“This is something we don’t do very often because then you have to modify everything else in the movement,” he says.

“It’s a bespoke engine, really.”

Aesthetics in motion

Step closer and the Ferrari DNA becomes unmistakable, from the strap modeled after Purosangue’s seats and the Prancing Horse emblem suspended in titanium, down to the smallest details.

A radial blade seconds display animates the dial, while torque, power reserve and function indicators form a dashboard reminiscent of a Ferrari cockpit.

The chronograph’s 30-minute counter sits prominently on the dial, reminiscent of the tachometer in a Ferrari 812 Superfast. Its skeletonized form reveals gear silhouettes that mirror the jagged contours of a Ferrari engine casing.

Up top, a tiny detail draws the eye: the barrel jewel setting, framed by a ring of micro-perforations, takes its cue from the clutch wheel of the F154 V8. On the back, X-shaped structures on the movement bridges evoke the extruded lattice found on Ferrari crankcases.

Hexagonal socket-head screws? They match those securing Ferrari engine covers, down to their 3N PVD gold finish, which extends to the arms of the split-second clamp. That warm gold hue calls to mind the legendary wheel hubs of the Ferrari P4.

It’s not just visual. It’s tactile. Hand-polished bevels, microblasted milled sections and lapped contact points add richness and depth to the already sculptural movement. Even the chronograph pushers echo the lozenge-shaped rear lights of the SF90 Stradale.

. (Photo courtesy of Richard Mille/.)

“In terms of performance, anything that has a technical purpose can also be beautiful,” says Ferrari design chief Flavio Manzoni.

“The concept of functional beauty is something that we really love.”

And in a nod to Ferrari’s precision marking, Richard Mille has, for the first time, engraved the watch’s reference number directly on the movement itself, flanked by stars, just like a Ferrari VIN. The famous “big F” logo appears on the rear bezel, another first.

The final lap

The RM 43-01 went through 10 prototypes to achieve the final design, a considerable number for a watch limited to just 150 pieces.

“The aesthetics actually come into the equation last, but obviously we must ensure that it all makes sense and looks good to the eye,” Arbona says.

. (Photo courtesy of Richard Mille/.)

It's a level of care that impressed the Ferrari team, which fine-tunes every detail in a virtual space long before prototypes take to the track, where they’re pushed in real-world conditions to see how they behave under pressure.

“The way they handle those tiny components is stunning. It doesn’t seem possible for a human to work on them with such precision,” Manzoni says.

For both Ferrari and Richard Mille, complication isn’t something to avoid. It’s a badge of honor.

“In watchmaking, they talk about complications, and that might seem like a negative word,” the Ferrari design chief continues.

“But it’s the other way round: complicating your life is the best way to showcase your ability to create those masterpieces. The easiest way in this instance is not the best way. It’s the most complicated way to do something fundamental: telling time.”

And like every Ferrari built for the road or the track, and every Richard Mille watch designed to be worn and tested, the RM 43-01 wasn’t made for ease. It was made for excellence.